Portal Frames in the Steel Building Industry

What Is a Portal Frame?

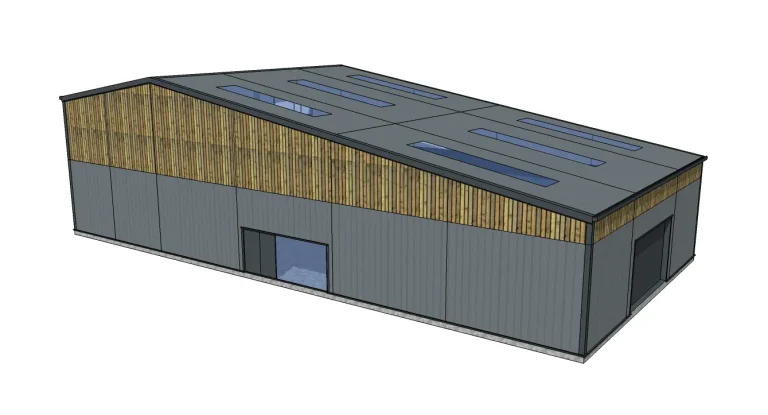

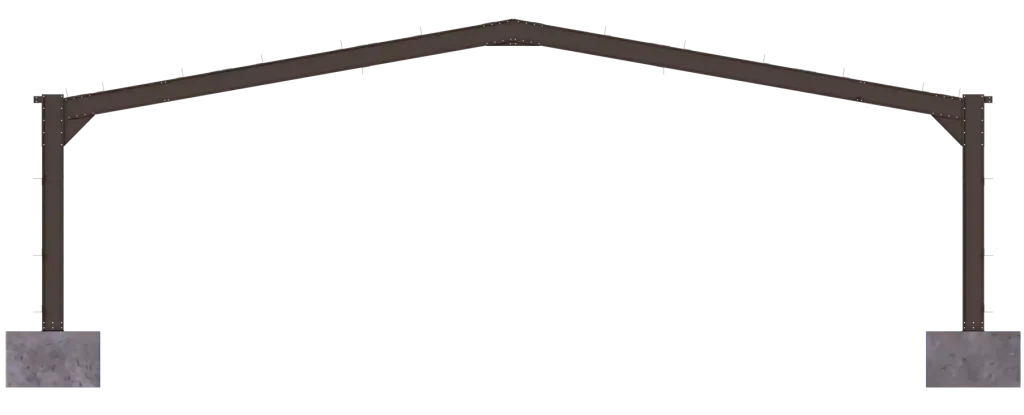

A portal frame is an industry standard structural frame design, used in low-rise steel building design. They consist of two columns and two pitched horizontal rafters meeting to create the ridge, that form a rigid, stable duo-pitch frame. The portal frame shape makes up the gable end of a building, and is repeated in parallel to create the length of a building in a set number of bays. The size of these bays and the width of the gable can be larger when using stronger hot rolled steel as opposed to cold rolled.

The rafters and columns are connected using haunch brackets, which help distribute the weight from the ridge, through the building to the ground. This allows for a clear span building, which means it has no internal props or columns obstructing the inside. These internal props can still be used if a clear span is not a requirement, sometimes coming in more cost effective as it can reduce the steel sizes.

Types of Portal Frames

Steel portal frames are versatile and commonly used structural solutions in construction. Selecting the right type depends on factors such as the building’s dimensions, intended use, and budget constraints. Below are some of the main types of steel portal frames and their typical applications:

Duo-Pitch Portal Frame

- Structure: Consists of two vertical columns and a two sloped rafters spanning across the structure creating a central ridgeline with equal pitches either side.

- Applications: Well-suited for buildings of all sizes, including garages, workshops, and storage sheds, due to its balanced design and efficient load distribution.

Multi Portal Frame

- Structure: A design that involves multiple portal frames placed side-by-side, creating two gables, and two roof ridges for a wider building footprint.

- Applications: Well-suited for larger buildings where multiple large openings such as expansive warehouses, industrial workshops and primarily aircraft hangars.

Offset Portal Frame

- Structure: A variant where the main structure is offset to one side, providing an asymmetric layout. Typically includes two columns with an offset or asymmetrical rafter arrangement, extending the roof farther on one side.

- Applications: Ideal for buildings with unique site requirements, irregular lot shapes, or where additional roof overhang is needed, such as in agricultural or storage buildings requiring extra sheltered space.

Mono-Pitch Frame

- Structure: The mono-pitch frame, also known as a single-slope or lean-to frame, consists of two columns with rafters sloping in a single direction. Unlike other portal frames, this design lacks a central ridgeline, with the roof sloping down from one side to the other.

- Applications: Mono-pitch frames are ideal for smaller structures, extensions, and spaces where one-sided drainage is advantageous. Commonly used for lean-tos, storage additions, or small industrial buildings, the mono-pitch design is cost-effective and suited for projects requiring a straightforward, single-slope roof profile.

Why are portal frames so popular, and what are the advantages?

A portal frame is the most economical design for the construction of low rise steel buildings. Several advantages make them an increasingly popular and most common choice for steel building design. One of the key advantages of using steel portal frames is their superior strength and durability. The portal frame is great at resisting wind, which is a necessity for coastal buildings where the wind is stronger. This means it is can be used for primarily industrial, storage and commercial applications which require a sturdy structure. This strong frame means that a portal frame can easily accommodate internal cranes such as gantry cranes.

Steel portal frames are the most economical and cost effective choice compared to other structural frame types because they are simple to manufacture and the well designed skeletal frame uses little materials making it easy and quick to assemble on-site. This makes them an excellent choice for businesses or clients that need to build new facilities quickly and efficiently, without compromising on quality or durability.

As mentioned before, the use of portal frames allows for large, unobstructed spaces inside the building, making it clear span, which can be particularly advantageous for applications where there is a need for maximum flexibility and versatility in the use of space, such as warehouses, workshops or showrooms. This is also greatly used in aircraft hangers, that may need to accommodate a plane or helicopter. This clear span design allows for this in the most efficient way.

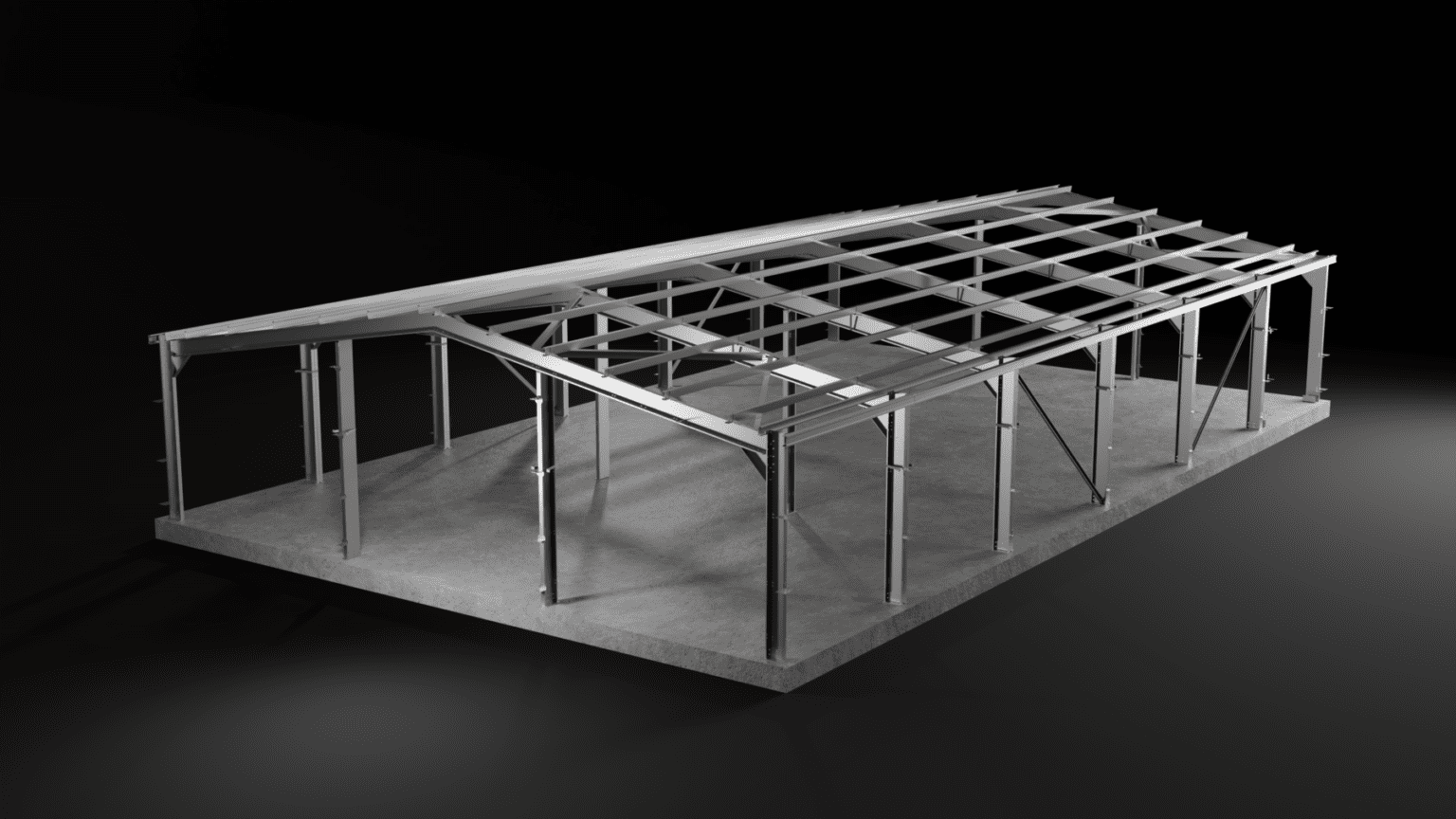

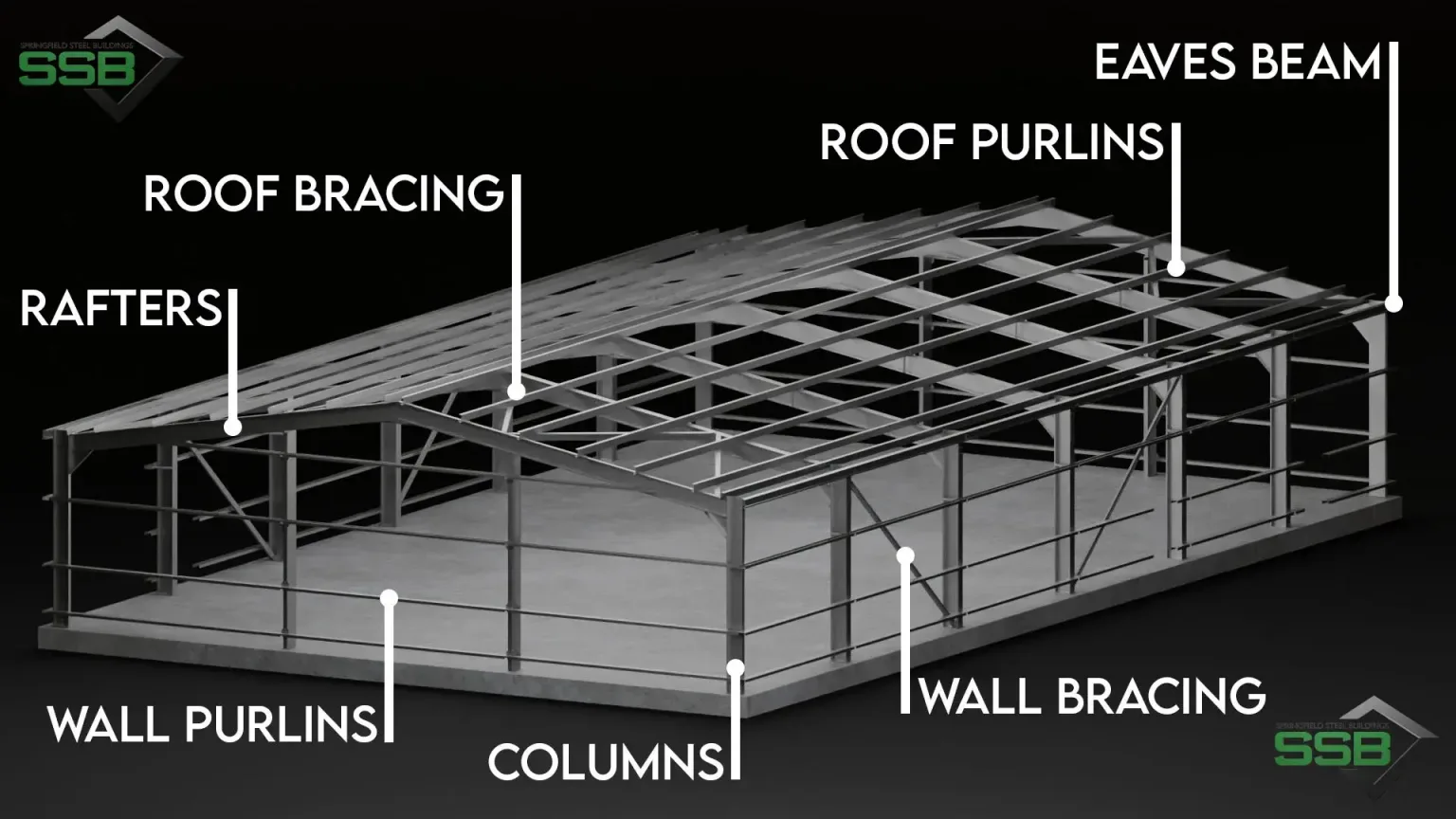

Design and Construction of Portal Frames

Portal frames consist of several key components, including columns, rafters, eaves beams, and purlins. The columns are typically placed at the corners of the building and provide the vertical support for the structure. The rafters are the horizontal beams that span between the columns and support the roof. Eaves beams connect the rafters at the bottom of the roof, and purlins are used to support the roof covering. Bracing in the walls and roof is very important as it can help larger buildings distribute the weight evenly, preventing pinch points.

You can click the buttons to the right to learn more about each component, and refer to our diagram below to see how each part makes up a portal framed building.

Columns make up the height of the portal frame,

but on their own they don't resist enough horizontal

and twisting forces to be strong enough. The connections to the

rafters creates stability across the gable. Mirroring this along

the length to create at least 1 bay is required to make the

structure stable in all directions.

Rafters are used to bridge the columns together. These are

pitched to more efficiently distribute the weight onto the

columns. This pitch can range from 5° to 20°, as shallower and

steeper than this can introduce unnecessary problems. The

added advantage of the pitched roof allows for rain and

snow run off.

Haunch Brackets are important because they strengthen the

rafter and column connections to reduce the bending moment.

They increase stiffness, resulting in reduced steel member

widths which makes the overall steel structure more cost

effective and efficient.

Calculating the size and spacing of the columns and rafters is a critical part of portal frame design. The loads that the frame will be expected to bear, such as wind, snow, and equipment, must be taken into account to ensure the frame is strong enough to withstand them.

Once the design has been finalised, the portal frame can be erected on-site. The columns are lifted into place using cranes and secured to the foundation using anchor bolts if it’s cold rolled steel, or fixed into concrete pads if it is hot rolled. When it comes to roofing materials, metal sheets, or cladding sheets, are often preferred for their durability, cost-effectiveness, and straightforward installation.

The advantage of portal frame construction on the site is that they can be erected relatively quickly and easily, especially when compared to other types of structural frames. This is because the components are typically prefabricated off-site and then assembled on-site, which saves time and reduces labour costs. At Springfield Steel Buildings, we prioritise using a nut and bolt system, which not only speeds up the installation process, but provides much more strength. They are also more economical, as there is no waste if the building were to be dismantled and rebuilt. Competitors within the steel building market often use tek screws, which can fail much easier and damage the steel members, which means they cannot be reused as easily.

In order to ensure the portal frame is erected correctly and safely, it’s important to prioritise professional construction. Springfield Steel Buildings can provide the expertise and guidance needed to ensure the portal frame is designed and constructed to meet all relevant building codes and standards.

Portal Frame Benefits

Portal frame roofing brings several unique benefits to steel buildings. Its design supports efficient rainwater management by directing runoff toward gutters and drainpipes, which protects both the structure and its surroundings from potential water damage. This roofing setup also minimizes the risk of pooling and enhances durability.

When it comes to roofing materials, metal sheets are often preferred for their durability, cost-effectiveness, and straightforward installation. Proper insulation is another key consideration for portal frame roofing, as it helps reduce energy costs and improve interior comfort. Selecting the right insulation type based on climate, location, and building purpose can significantly enhance energy efficiency.

Portal frames can be designed to support internal gantry or overhead cranes. This makes them ideal for factories and manufacturing plants where heavy equipment and goods need to be moved efficiently within the building.

With appropriate fire-resistant coatings, steel portal frames can meet stringent fire safety requirements, making them suitable for buildings where fire risk management is essential, such as manufacturing facilities, storage units, and warehouses.

Uses For Portal Frames

Portal frame buildings can easily make use of insulation, which helps reduce heating and cooling costs. When tailored to the building’s location and climate, proper insulation contributes to a comfortable interior environment and energy savings over time. Insulation is often fixed to the building through cladding, which means it can be easily swapped out if there is an issue, or easily upgraded to a thicker insulation.

With a modular design, portal frame buildings are easy to expand. Additional bays or extensions can be added without major structural alterations, which is perfect for growing businesses or organizations that may need to scale up in the future.

Comparing Portal Frame Structures to Other Steel Building Systems

When planning a steel building project, it’s important to understand how portal frame structures compare to other framing methods. Portal frames are the go-to choice for low-rise, wide-span buildings thanks to their simple design and minimal material usage. Unlike trussed systems, which often require additional internal supports, portal frames use rigid haunches and tapered rafters to create large, open internal spaces without obstructions.

Modular steel systems, while useful for rapid deployment or temporary solutions, typically lack the long-term structural efficiency and durability of portal frame buildings. At Springfield Steel Buildings, we specialise in steel portal frames because they offer the best combination of structural strength, speed of erection, and cost-efficiency; particularly in commercial, industrial, and agricultural applications.

Do Portal Frame Buildings Meet UK Building Regulations?

Yes, steel portal frame buildings are fully compliant with all relevant UK building regulations when correctly designed and installed. At Springfield Steel Buildings, our engineering process ensures that each structure meets the necessary standards for structural integrity, fire resistance, insulation, and environmental performance.

We design to the proper standards for structural steel, which cover everything from wind and snow load resistance to frame stability and connection safety. Our buildings can also incorporate insulated cladding and fire-rated components to meet the needs of industrial and commercial premises that require higher levels of protection. Compliance is built into our process, giving clients confidence in both quality and regulatory approval.

Can Portal Frame Buildings Be Customised for Unique Requirements?

Absolutely. One of the biggest advantages of a steel frame portal design is its flexibility. At Springfield Steel Buildings, we tailor every project to meet the specific needs of the site, purpose, and client. From non-standard bay widths to varying roof pitches, eaves heights, and opening placements, portal frame buildings can be designed around your requirements.

Need extra wide roller doors, integrated office space, or additional insulation for temperature-sensitive storage? We can incorporate all of that into your custom steel portal frame building. Even internal layout elements like partition walls, mezzanines, and ventilation systems can be planned from the outset, ensuring optimal usability without compromising structural integrity.

Advancements in Portal Frame Technology

Portal frame technology has come a long way in recent years, with advancements in materials and techniques allowing for even more versatile and efficient designs. For example, new high-strength steel alloys are now available, allowing for lighter and more cost-effective portal frame designs. Advances in computer modelling and simulation also make it easier to design and test portal frames, ensuring they meet the highest safety and performance standards.

Looking to the future, it is likely that portal frames will continue to be a popular choice for steel building construction. As new materials and techniques become available, we can expect to see even more innovative and efficient portal frame designs. However, it is important to remember that no matter how advanced the technology becomes, the basic principles of portal frame design and construction will always remain the same – creating strong, stable, and efficient structures that meet the needs of the building’s users.

FAQs

What is the difference between a portal frame and a truss frame?

A portal frame uses rigid connections between columns and rafters to create a strong, self-supporting structure with large, open spans and no internal supports. Truss frames, by contrast, use triangular sections made of smaller members and often require additional internal bracing. Portal frames are more efficient for low-rise buildings like warehouses and workshops due to faster installation and reduced material usage.

Are portal frame buildings suitable for UK weather conditions?

Yes, steel portal frame buildings are well-suited for UK weather, including high wind and snow loads. At Springfield Steel Buildings, our structures are engineered to meet British Standards, ensuring long-term performance in all environments. The pitched roof design also promotes water runoff, preventing pooling and structural stress.

Can portal frame buildings be extended in the future?

Portal frame buildings are highly adaptable and can be extended by adding additional bays. This modular approach allows growing businesses to scale up their operations without major structural changes. At Springfield Steel Buildings, we design each frame with expansion potential in mind where required.

Do portal frame buildings require planning permission in the UK?

Most portal frame buildings will require planning permission, especially if they are intended for commercial or industrial use. Factors like size, location, and intended use will determine whether full planning approval or permitted development rights apply. We can help guide you through the process or work with your appointed planning consultant to ensure compliance.

How long does it take to construct a steel portal frame building?

Construction times vary depending on size and complexity, but most steel portal frame buildings can be erected in a matter of weeks. At Springfield Steel Buildings, we use a prefabricated nut and bolt system that speeds up on-site assembly and minimises disruption. This approach also reduces labour costs and accelerates project timelines.